|

OxiX is an innovative, bio-friendly, rust and

oxidation barrier that preserves and protects all metals and a lot

more. It can be used as a stand alone sealer or as a primer that can

be painted over with excellent adhesion. OxiX dries within minutes

providing you with a durable moisture and oxidation barrier on your

surfaces that will last for years. OxiX can be applied over rusted

or oxidized surfaces to prevent further corrosion. Even if the

coating is penetrated OxiX will stop the acceleration of corrosion

creep back.

OxiX is crystal clear for coating aluminum, galvanized coatings, and other surfaces. It can also be tinted to colors when used as a paint primer and or top coat.

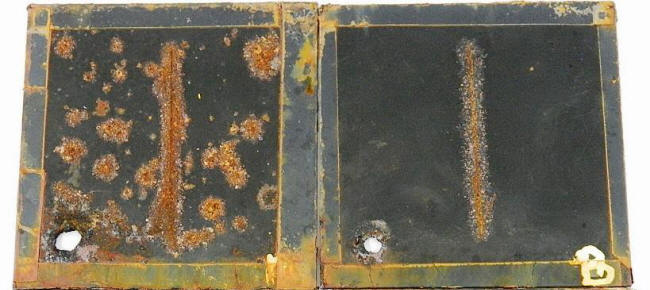

Oxix has been tested by an outside laboratory (Assured Testing Services) The test being performed is SAE J2721 Paragraph 10.2 (We are doing the combination of road salts dip procedure) This is the most accurate and aggressive testing known for testing corrosion. It is also the test to pass for the entire commercial transportation industry. Please see pictures from the laboratory showing test results below: Testing completed by outside accredited labortory: Assured Testing Services Accredited to ISO 17025, NADCAP, and AAMA SAE J2721 Testing: Every test cycle is 24 hours and every 8 cycles is equal to 1 year in harsh road salt conditions in a far northern climate. Panel A (On Left) is unprotected by Oxix and painted with top quality paint. Panel B (On Right) was primed with OxiX and top coated with the same top coat as panel A. After 80 cycles (Equal to 10 years of road salt environment) in the SAE J2721 testing procedure, Oxix is protecting (panel B) from red rust blossoming and stopping creep back on the scored cut into the steel.

Bare Aluminum Panels: AL-3 has been protected by OxiX and AL-0 has not been protected

Galvanized Steel Panels: G-0 is unprotected galvanized steel and G-3 is protected by OxiX.

Product News One of the worlds largest semi-trailer manufacturers incorporates OxiX into their operations. After extensive in-house SAE J2721 testing, OxiX has proven to protect their aluminum panels, rivets, and rails from harsh northern road salts. An operation has begun on all repaired warranty trailers. OxiX will be used to coat all these trailers to prevent any future corrosion issues. After wetting their feet with warranty work, they are expected to coat all new production semi-trailers with OxiX. "Why not prevent the corrosion warranty work from the beginning and remove the high cost of doing it." OxiX Testimonial from

Featherlite Trailer Manufacturers Featherlite has started using OxiX primer as it is an excellent corrosion inhibitor and it has no VOC’s which reduces our environmental footprint. Featherlite has found the primer to be very durable and very effective for eliminating corrosion even against the new calcium chloride salt brine and other solutions some states are placing on roads for snow/ice removal.

Kevin Weinacht, OxiX Adhesion Test Featherlite performs periodic adhesion testing on OxiX primer and other coated surfaces. Paint adhesion testing is often used to determine if the paint or coating will adhere properly to the substrates to which they are applied. Adhesion Testing provides valuable information about the overall bond strength and performance of a coating. Featherlite uses the ASTM D 3359-02 Cross-Cut Test method when testing coating adhesion. This test consists of a right angle lattice pattern or X-cut (contingent on paint thickness) and is the standard used to measure the resistance of paints and coatings to separation from substrates. The pattern is cut into the coating and penetrates through to the substrate. A pressure sensitive tape is applied to the sample and pulled off. Featherlite has tested several samples of steel and aluminum that were coated with OxiX primer. Some samples were contaminated with grease and oils, some were uncontaminated. The metal substrates were cleaned, prepped and coated with OxiX. In almost every application the test received a 5B classification on a B scale. The B scale classification ranges from 0B which has greater than 65% material release to 5B which has 0% material release. When Featherlite performed Cross-Cut testing on metal substrates with OxiX primer covered with a paint top coat, the tests came back equally as impressive. The tests received 5B and 4B classification ratings. I don’t think you can ask for more than that in a coating” George Willis Please contact us for more information and free product samples: Streak Master, Inc. Contact: Greg Waltrip 214-912-3368 Email Us |